- Home

- Sustainability

- Initiatives for Environmental Conservation

Harima’s unwavering commitment to protecting the environment stems from our identity as a pine chemical manufacturer that promotes products developed using natural and renewable resources. In light of our corporate philosophy and environmental policies, we are committed to actively contribute to the realization of a sustainable society.

In compliance with ISO 14001, the international standard for environmental management systems, we have established a structure that oversees the entire company while carefully monitoring each site through internal audits and environmental committees. The committees set annual targets using the Sustainable Development Goals (SDGs) as guidance, in areas such as greenhouse gas (GHG) emission reduction and waste management.

We encourage all sites to commit to ISO 14001 as part of our continuous effort for environmental conservation. Acquisition status at our sites in and outside Japan is as follows:

| Company | Date | Certification Body |

|

|---|---|---|---|

| Harima Chemicals Group | Kakogawa Plant | Jun 2000 | JCQA |

| Fuji Plant/Sales Office | Mar 2002 | JCQA | |

| Tokyo Plant | Jun 2004 | JCQA | |

| Ibaraki Plant | Jun 2006 | JCQA | |

| Sendai Plant/Sales Office | Dec 2014 | JCQA | |

| Shikoku Plant | Dec 2014 | JCQA | |

| Harima M.I.D., Inc. | Jun 2000 | JCQA | |

| Nippon Filler Metals, Ltd. | Jul 2005 | LIACA | |

| Company | Date | Certification Body |

|---|---|---|

| Harimatec Hangzhou Co., Ltd. | Oct 2004 | CQM |

| Harimatec Inc. | Feb 2007 | UL |

| Hangzhou Hanghua Harima Chemicals Co., Ltd. | Nov 2007 | CQM |

| Harimatec Czech, s.r.o. | May 2013 | CERT |

| Shandong Hanghua Harima Chemicals Co., Ltd. | Nov 2016 | LYEC |

| Dongguan Hanghua Harima Paper Chemicals Co., Ltd. | Dec 2019 | CQM |

| Harimatec Malaysia Sdn. Bhd. | Oct 2023 | UKAS |

| LAWTER - Mt. Maunganui | Apr 1999 | TELARC |

| LAWTER - Maastricht | Jan 2001 | DNV |

| LAWTER - Nanning | Jul 2010 | CNAS |

| LAWTER - Kallo | Oct 2014 | DNV |

Belgium

LAWTER – Kallo

LAWTER - Kallo has obtained the ISO 50001 certification, an international standard for energy management systems, and plans to reduce 30% of CO₂ emissions by 2030, in comparison to FY2013, and further employ measures for energy conservation and promote eco-friendly operations.

The company acquired ISCC PLUS and ISCC EU certifications in January 2025.

ISCC - International Sustainability and Carbon Certification, is a certification system for the implementation of sustainable and traceable supply chains, free from deforestation. It can be applied globally in all markets including industrial, chemical, energy, and animal feed.

Harima uses crude tall oil (CTO), a byproduct obtained during the manufacturing of pulp from pine trees, and distills it to extract rosin, fatty acids, and turpentine, the core raw materials of our products. ISCC attests that the CTO we procure and the related products are thoroughly managed throughout the supply chain. This reaffirms the sustainability and traceability of our biomass-based products, thus creating new business opportunities.

Our principal subsidiary, LAWTER was granted an EcoVadis gold medal in May 2024. This is its second gold medal, following acquisition in 2018.

EcoVadis is the world's most trusted business sustainability rating provider. Since its founding in 2007, the France-headquartered organization has evaluated more than 130,000 companies from over 200 industries and 180 countries, as of 2024.

LAWTER was highly evaluated on the criteria of environmental protection, ethics, labor and human rights, and sustainable procurement, and the current gold rating places it in the top 5% companies assessed by the platform.

Our domestic sites acquired a B-score in CDP 2024 for “Climate Change” and “Water Security."

CDP is an international environmental non-governmental organization that evaluates and discloses strategies and initiatives of companies and municipalities regarding climate change. It collects and analyzes information disclosed by companies and municipalities worldwide, assessing their efforts on an eight-level scale (A, A-, B, B-, C, C-, D, D-). CDP is widely recognized as a global standard for corporate environmental disclosure. In CDP 2024, more than 24,800 companies worldwide responded, and over 2,100 Japanese companies—including more than 70% of those listed on the Prime Market—disclosed information through CDP. The B-score achieved this time indicates a management-level evaluation, meaning the company is “aware of its environmental risks and impacts and is taking action.”

We will continue to provide transparent disclosures on climate change and natural capital, aiming to contribute to the realization of a sustainable society, while also enhancing corporate value and further advancing our sustainability initiatives.

Preserving biodiversity is a crucial aspect of environmental conservation. At Kakogawa Plant in Japan, we utilize its spacious area to cultivate various plants including bonesets, an endangered species that has been red-listed by both regional and national authorities. Their numbers have decreased significantly in recent years due to urban development, construction work and herbicide use. We will continue efforts to protect the local vegetation for a vibrant and diverse ecosystem.

Components resulted during crude tall oil distillation are used as biomass fuel, letting us utilize every bit of the raw material’s value. In Mar 2005, we established our very own biomass power plant at Kakogawa Site, and since 2009, more than 60% of all energy is sourced from biomass. Decrease in production at related paper companies due to the pandemic as well as higher CTO prices have caused difficulties in the procurement of raw materials, leading to lower rates of biomass fuel used.

We strictly monitor SOX, NOX, and Chemical Oxygen Demand (COD) emissions, and periodically modernize manufacturing equipment and processes to limit their environmental impact, such as implementing low-NOX burners for boilers and using high-quality fuel and desulfurizers to curb emissions.

While energy use is now an indispensable part of everyday life, we continue to explore energy sources that can successfully replace fossil fuels. Renewable resources are instrumental in achieving this goal, as non-depleting materials are essential to a sustainable future. Having worked closely with nature for over 70 years, we are committed to making efficient use of renewable resources and reducing environmental impact.

Our use of biomass fuel has contributed significantly to reducing CO2 emissions. In 2005, we opened a biomass power plant at Kakogawa Site with the capacity to fulfill all steam and power needs of the site, and any surplus power is supplied to local electricity companies as green energy.

Our biomass power plant at Kakogawa Site was approved by the Japanese Ministry of Economy, Trade and Industry in FY2003 as a green initiative for the future of energy production and was opened in Mar 2005. The facility uses components resulted during crude tall oil distillation, letting us utilize every bit of the raw material’s value. The plant has the capacity to fulfill all steam and power needs of the site, and any surplus power is supplied to local electricity companies as green energy so that nothing goes to waste. In addition, biomass power contributes significantly to reducing CO2 emissions.

Transition to Greener Energy Sources

As municipal gas and liquefied natural gas (LNG) emit significantly less CO₂ than heavy oil and kerosene, we are actively involved in converting to these cleaner fuels in our operations.

Saving Energy Through Visualization

We have implemented a monitoring system that helps visualize energy consumption at our production sites, to detect energy loss and optimize manufacturing processes. Visualization also raises awareness among employees and encourages improvements in the workplace.

We collaborate with logistics companies to reduce CO2 emissions in our fully outsourced distribution operations. We aim to increase use of rail and marine transportation, which have lower CO2 emissions compared to trucks.

In Dec 2014, we opened a solar power plant with a capacity of 1,129kW at the Iho Site in Japan. Through the "Feed-in Tariff (FIT) for Renewable Energy" policy that guarantees a fixed price for electricity sale, all generated power is distributed to local electricity companies. By utilizing our facility to generate solar power, we contribute to the promotion of green energy and reduction of CO₂ emissions, also in light of the latest related initiatives promoted by the Japanese government.

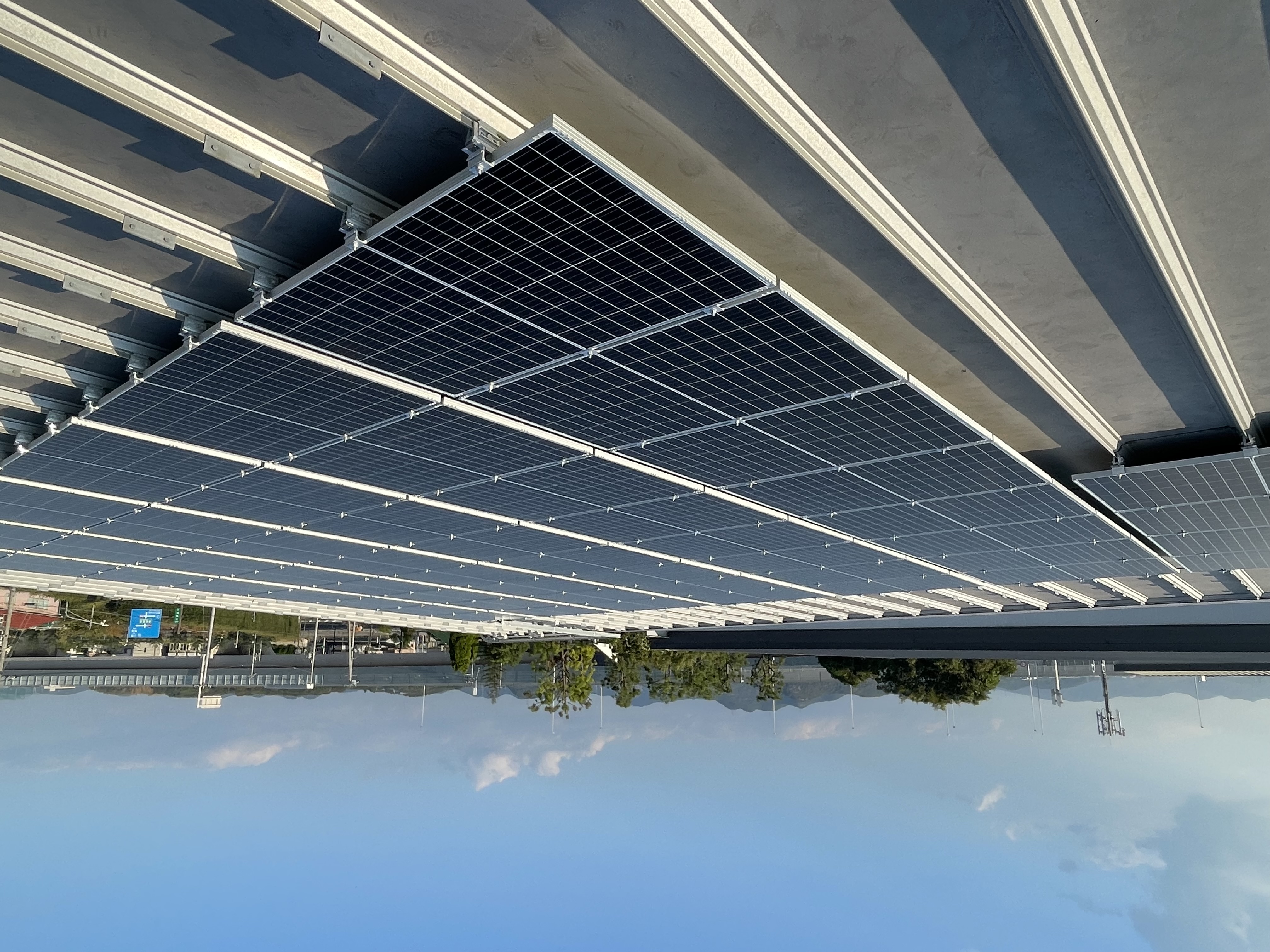

In Mar 2023, Harima started its first floating solar-power generation business on a reservoir located in the vicinity of the Kakogawa Plant. Our approx. 1,700 solar panels installed on structures on the surface of the reservoir generate an annual 1 million kWh, representing enough power to supply the electricity needs of 250 homes, also reducing carbon dioxide emissions by about 380 tons. The power is distributed to the Kakogawa Site via a private transmission line, and also to a local community center for everyday use, as well as for emergency situations when an accumulator and power conditioner will also be on standby.

This project is partially funded by the Ministry of the Environment, Japan (MOEJ) through an emission mitigation grant program, and in Apr 2023, was acclaimed as a model case for solar power facilities implemented in innovative locations such as farmland, reservoirs and waste treatment plants. It is featured on the MOEJ website, recognized for its significant contributions to the environment and the community, as well as disaster resilience through the distribution of electricity for everyday and emergency use.

The project reiterates Harima's long-standing commitment to protect the environment, give back to the community, and enhance business all at the same time.

The Kakogawa office of Harima Trading introduced a solar-power system in December 2023. The office runs warehouse management operations that cater to customers from a variety of industries, assisting them in the distribution of goods in a timely and efficient manner. The introduction of a solar-power system means that a portion of the power used at the facility will be replaced with green electricity, as part of a larger plan to strengthen environmental preservation activities. The office also intends to replace all its electricity with eco alternatives in the near future.

Kakogawa Plant introduced the EnneGreen Plan in April 2023, which has resulted in eliminating carbon dioxide emissions from electricity use. Provided by Japan-based Ennet, the plan successfully pairs utilization of electricity with a non-fossil fuel energy certificate which serves as proof that electricity originates from renewable energy sources.

In addition, we introduced the Green Basic Plan at our Ibaraki, Tokyo and Fuji Plants in Japan, which partly replaces purchased electricity with renewable energy. Provided by Japan-based TEPCO Energy Partner, the plan successfully combines FIT* and non-FIT non-fossil fuel energy certificates.

*FIT: Feed-in Tariff Scheme for Renewable Energy

Argentina

LAWTER - Concordia

In an effort to reduce CO2 emissions, LAWTER - Concordia has implemented a solar power system on its premises. The power is generated for on-site use, contributing to the further promotion of renewable energy.

We stay true to our circular business model by strictly managing waste, in addition to reducing waste generation and encouraging recycling.

Landfill use is a less-visible aspect of emission that only occurs at the very end of a product’s life cycle. In the past, landfill disposal rates were over 2%, mostly composed of residue from biomass combustion that could not be processed any further. In FY2005, we discovered a way to recycle the residue by using it for cement, gradually shifting landfill use to less than 1%. The rate was further reduced to zero in FY2011 when we established means to recycle waste glass, accomplishing the zero-emission level we maintain today.

Energy consumption and CO2 emissions of overseas subsidiaries are calculated using factors established in related Japanese laws and international regulations.