Harima Develops Release Film for Semiconductor Molding

Dec 11, 2024

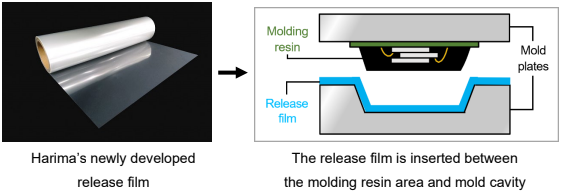

Harima has developed an advanced release film for use in the molding of semiconductors. Its unique properties help optimize production while also mitigating environmental load. The film has been successfully introduced to potential customers in and outside Japan, and we are aiming for a 30% market share by 2030.

Utilized in the compression molding of semiconductors, the film is inserted between the molding resin area and the mold cavity, to protect the mold from the excess material cured. The film also protects from sublimates that form during molding, eliminating the necessity for frequent cleaning and so decreasing process time and operation costs. Its versatile design allows for use with a wide range of items, for both silicone and non-silicone applications. In addition, it is PFAS-free which helps diminish environmental impact throughout the supply chain, thus meeting the increasing need for more sustainable and circular solutions.

■Core Features

・Protects from sublimates that form during molding

・Versatile design allowing for high customization

・Available for both silicone and non-silicone applications

・PFAS-free

■Expo Info

Our new product will also be presented at NEPCON Japan, Asia's leading exhibition for electronics R&D, manufacturing and packaging technology, scheduled for January 22-24,

2025 at Big Sight, Tokyo. Details available here:

https://www.harima.co.jp/en/newsroom/2024/1202143141.html

■Contact

Public Relations, Harima Chemicals Group, Inc.

URL:https://www.harima.co.jp/en/inquiry.php