Electronic Materials Business

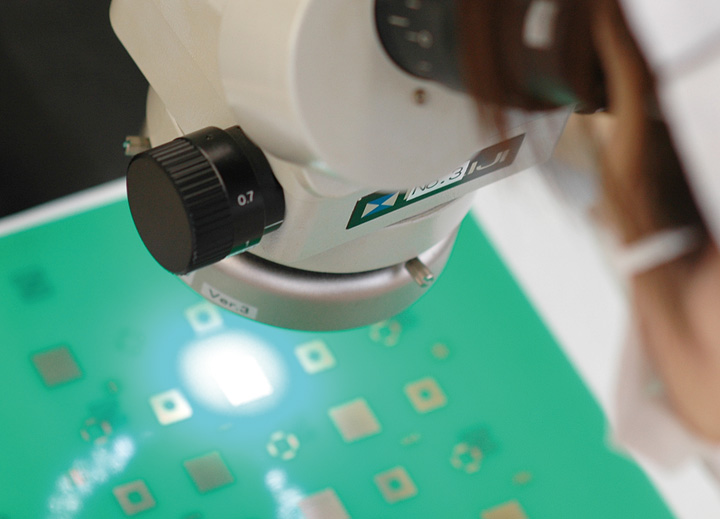

Harima’s electronic materials business covers the development, manufacture and sale of items like solders and conductive pastes used to mount microchips and form electronic circuits for today’s increasingly compact high-performance electronic devices.

Harima technology can be summed up as one that is both Clean (eco-friendly) and Fine (compact and highly functional). We conduct our daily business activity with this philosophy in mind and bring value-added proposals to customers. Whether it is the low-cost micro soldering technologies that contribute to miniaturization, or independently developed multifunctional materials capable of shortening the production time of electronic devices, we offer the latest innovations.

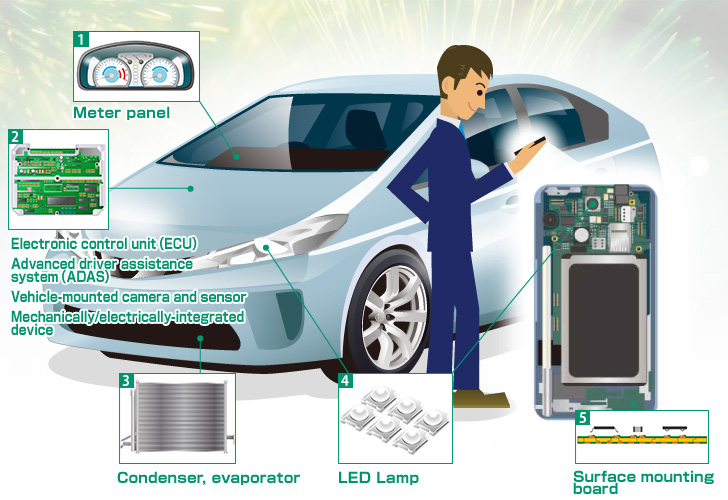

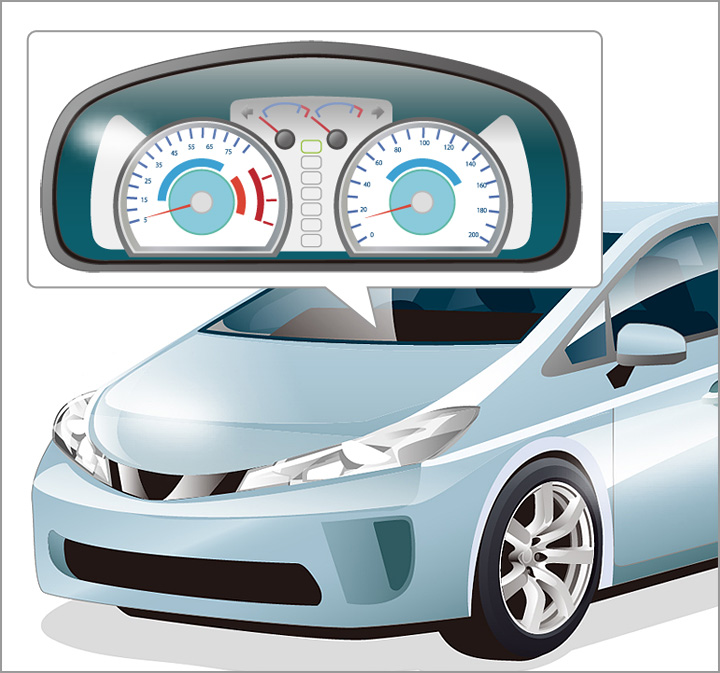

1Meter panel

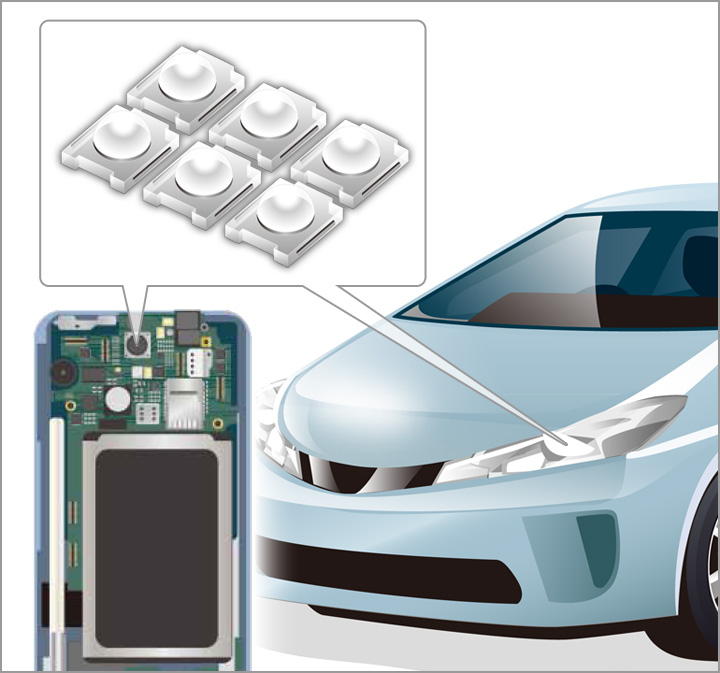

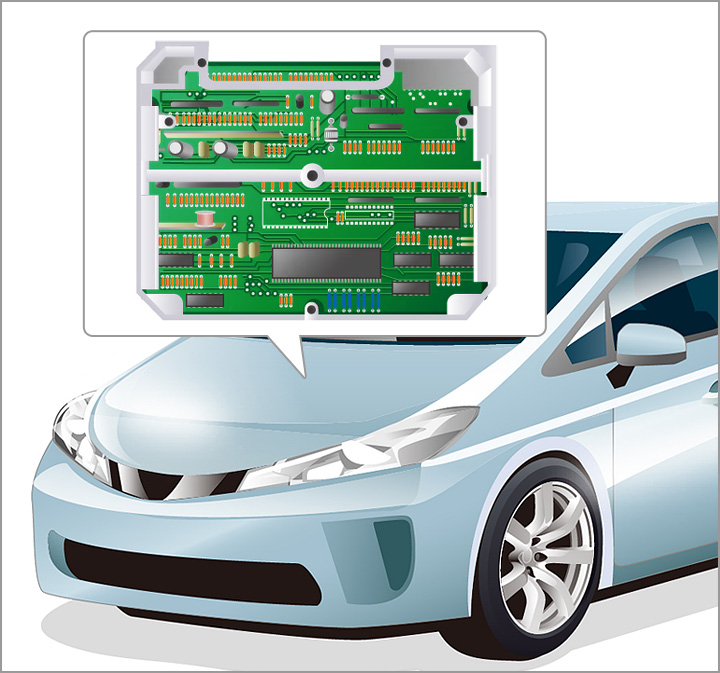

2Electronic control unit(ECU)/Advanced driver assistance system(ADAS)/Vehicle-mounted camera and sensor/Mechanically/electrically-integrated device

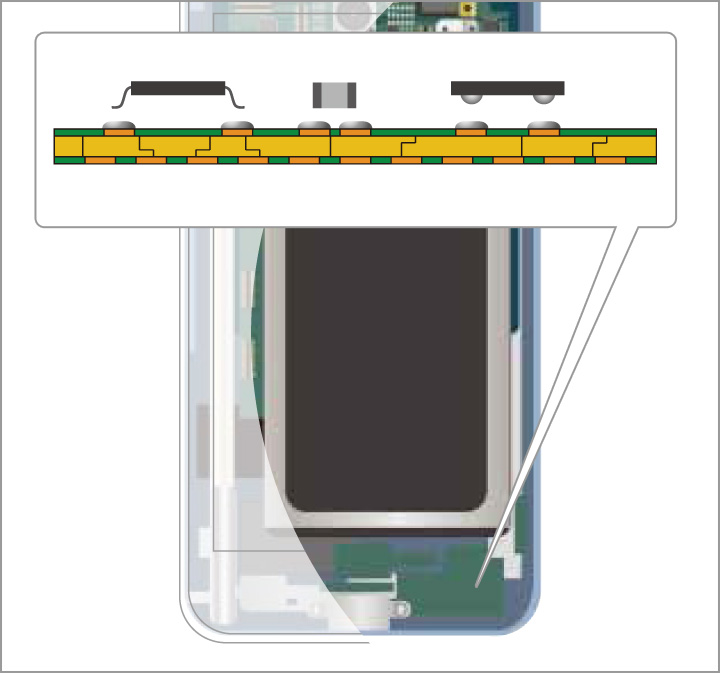

5Surface mounting board

- Halogen free solder paste (330K)

- Low-silver lead-free solder paste (211K)

- 0201 chip compatible solder paste (234K)

- Sn-3.0Ag-0.5Cu lead-free solder paste (2,312K)

- High Adhesive NANOPASTE® (176K)

Solder Materials

Solder is a material used to form a joint between electronic parts and substrates during the manufacture of electronic devices such as mobile phones and computers. One variety called solder paste is a creamy mixture of fine metal powder and other materials which include rosin. We have applied the decomposing effect of rosin on metal oxides to develop unique solder pastes by mixing metal powder with rosin derivatives. We believe it is our duty to protect the environment, and as such were one of the first to develop lead-free solder pastes as a means to prevent the devastating impact that lead has on the environment when it leaches from old or discarded electronics due to acid rain. Ever since our lead-free solder pastes were used to produce the world’s very first lead-free MD player in 1998, it has become widely adopted.

Materials for Printed Circuit Boards

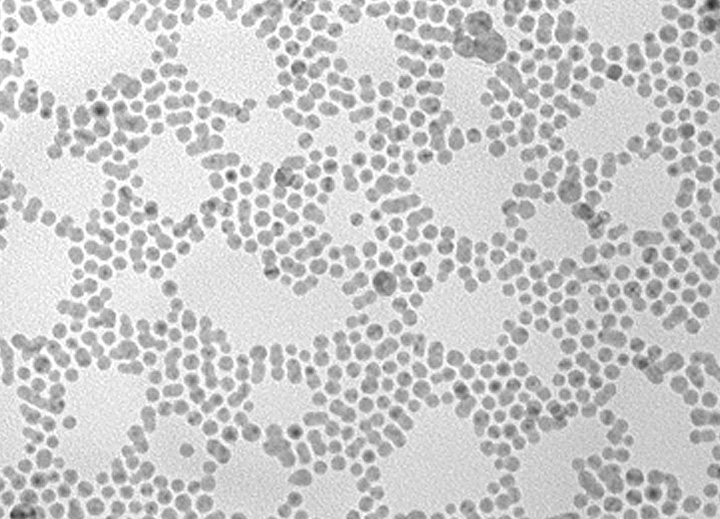

Conductive paste is, as the name suggests, an electrically conductive adhesive. Harima’s extensive knowledge acquired in the fields of coating and adhesion resins has made it possible for us to create conductive pastes that, for example, facilitate the release of heat generated by electronic devices (thermal conductivity) to allow for higher density of parts to be mounted. Also characterized by its high reliability and compatibility with various printing methods, conductive pastes have become an indispensable soldering material in the parts assembly of next-generation electronics devices such as solar cells and smart phones. Another of our conductive pastes is NanoPaste, a stable distribution of nano-sized* metallic particles in ink-form that only needs to be applied and heated to form a highly reliable metallic membrane for a wide-range of joint and wiring applications. NanoPaste’s applicability to various printing methods, including inkjet, has made it a prime candidate as a core material in the area of printed electronics.

*Nano-size denotes one billionth of one meter.

Stable distribution is achieved by controlling the dispersion agents.

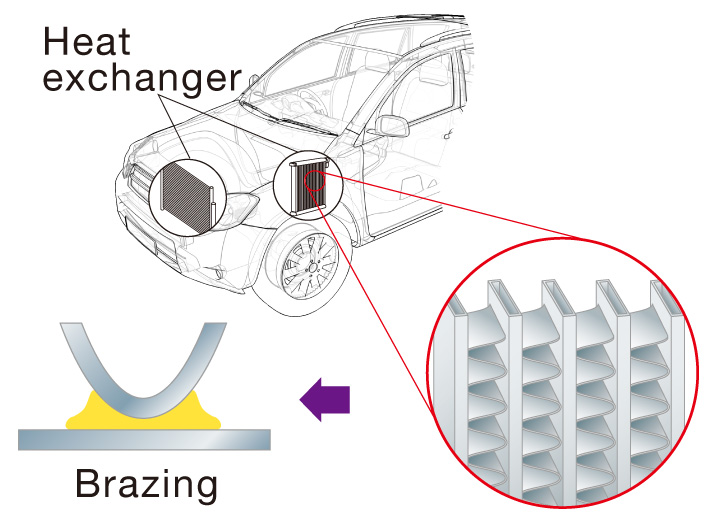

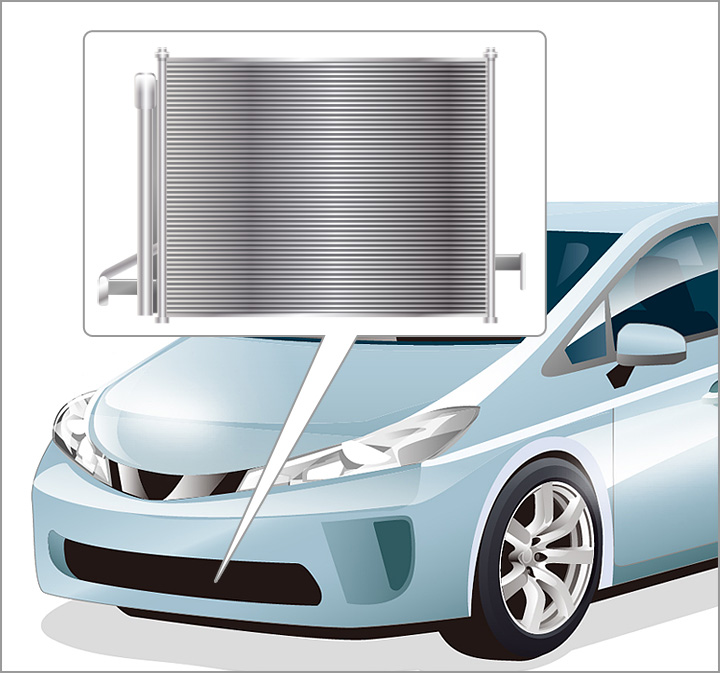

Brazing Materials for Heat Exchangers

Brazing technology used to join aluminum is another application of Harima’s extensive know-how. Aluminum brazing materials used in the manufacture of all kinds of aluminum products contribute to enhanced quality and reduced costs. Aluminum is commonly employed as a weight-saving measure in heat exchangers, which are an essential part of engine cooling and air conditioning in automobiles, making it necessary to braze aluminum parts of varying shapes together. Conventional manufacturing methods involved spraying the materials needed for brazing on to the entire surface of heat exchanger member and then heating. However, the aluminum brazing material we engineered is an extension of our precoating technology and only requires that a minimal amount of brazing material be supplied just to the immediate brazing area, realizing drastic cost reductions and higher quality.